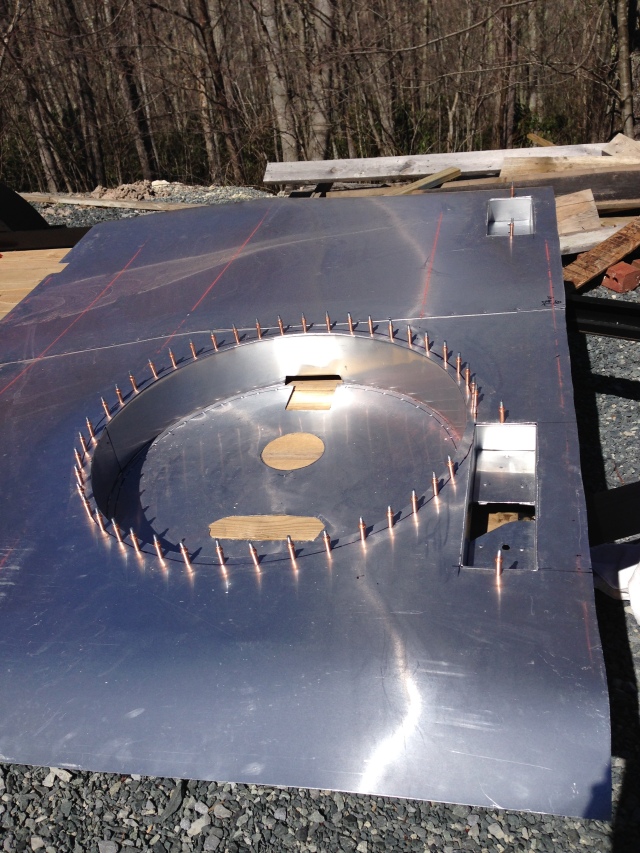

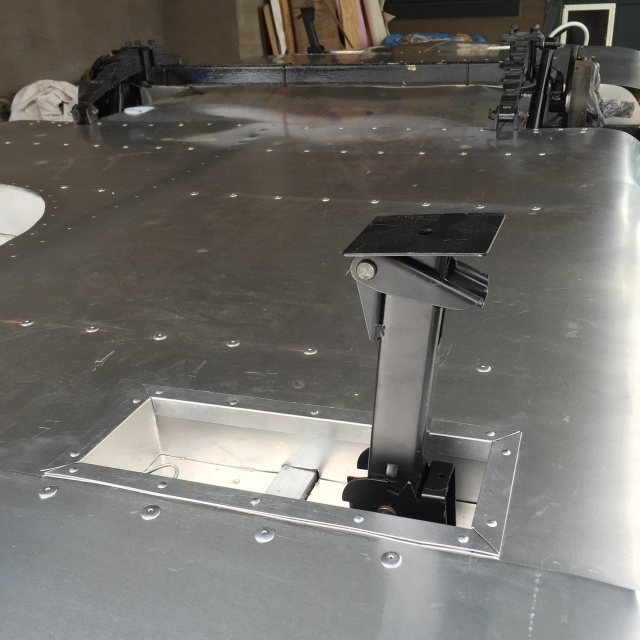

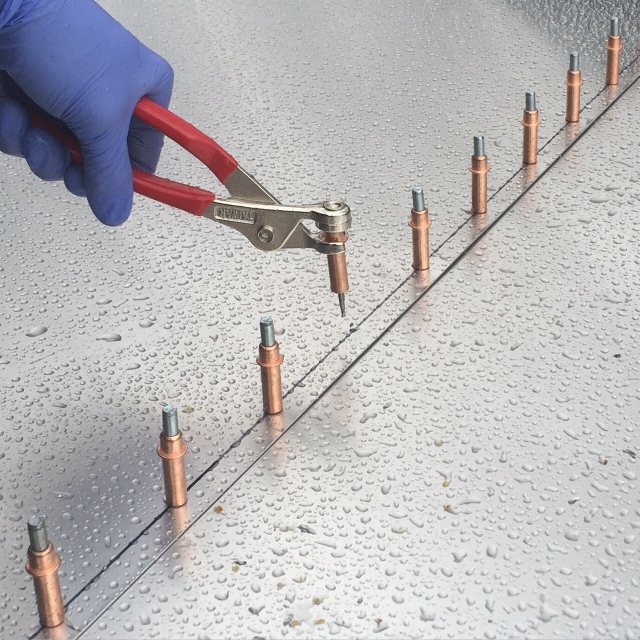

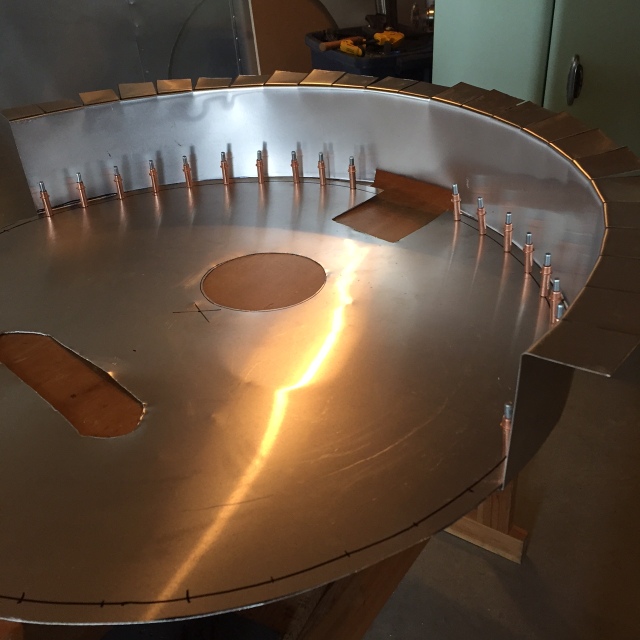

We patched two holes in the roof from the original furnace and fridge with one patch.

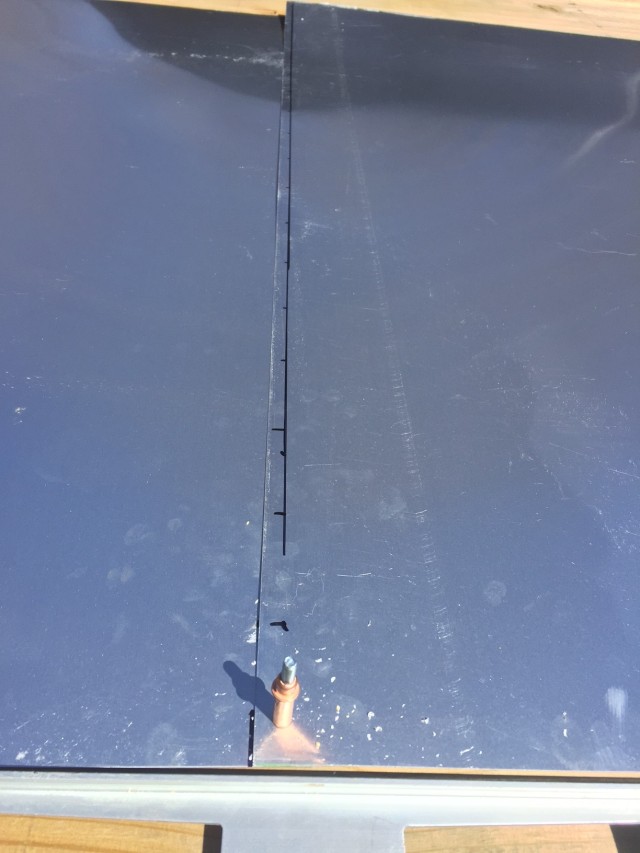

Every inside seam is fully caulked.

We spent many cold days inside rebuilding the last few side windows and polishing the interior window hardware.

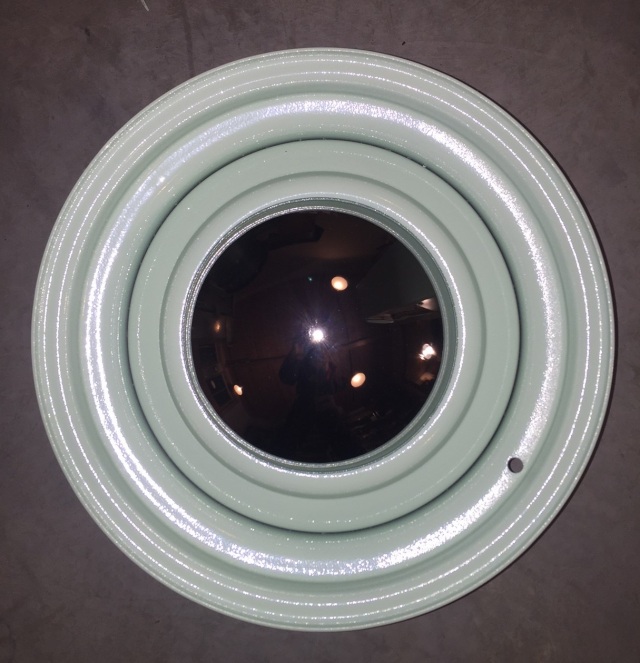

The rear window frame was a mess. Now it is shiny and ready for the new rear window. We also spent some time tracking down new seals for the rear and front windows. Vintage Trailer Shop & Steele Rubber Products were very helpful.

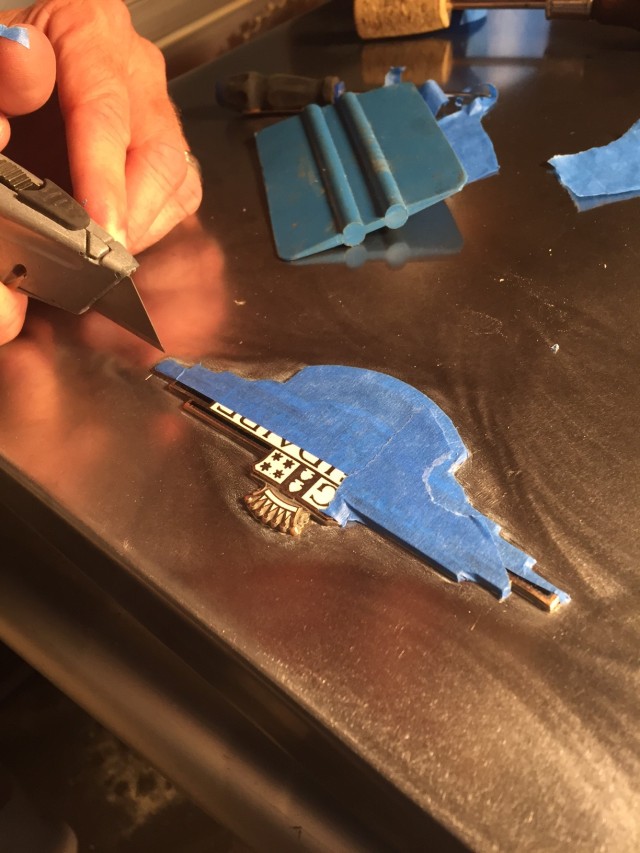

The door has been the biggest project so far this year. In the process of installing a new lock and deadbolt we also fabricated a couple of new panels. There has been a lot of putting things together and taking them apart…then making some adjustments and putting it all back together again…and on and on. It’s nearly ready to reassemble and insulate with spray foam. Then we’ll polish the rebuilt door for an introduction to polishing.

We spent a little over 100 hours during January and February bringing the total hours to 1,525 so far for the whole project.